RIBA plan of work stage 5

Stage 5 is the manufacturing and construction phase of development.

The design team does most of their work at Stage 4, but it’s possible for them to overlap Stage 4 and Stage 5, as dictated by the project schedule.

The construction team does most of their work at Stage 5.

This is usually dictated by the procurement route selected (e.g. design and build, traditional, etc…).

The information provided to the design team at Stage 5 is changing. Design teams may receive data that ranges from a 2D general arrangement produced by the design team to a multi-disciplinary model containing specialists vendor info and lots of supplementary data for maintaining the asset, operating it, or using it.

The information needs to be correct for you to use the building properly. Just because your project is small, doesn’t mean there won’t be any Building Systems that need to be operated effectively in order for your building to function as expected.

It can be difficult at the start of your project or with constantly-changing industry standards and software to know what Information Requirements are necessary, but as you continue along you should be able to tell if the contractual responsibilities will meet their informational needs.

Each client has their own individual needs, and it’s important to consider those needs.

For some clients, the design team is responsible for inspecting the building for compliance with the Building Contract. For other clients, this inspection will be handled by someone else on their end.

The need for Site Queries also varies from project to project.

RIBA plan of work Stage 6

At stage six of the project, the building will be complete and the focus will shift to fixing any issues that arise and making sure that all tasks are completed in order to conclude the contract.

To ensure the successful handover of a building and to ensure that it will perform as planned, it’s important to consider the plan for use strategy carefully. Handover activities may take place during stage 5, in order to make sure objectives are met. The end of stage 5 should be defined as when the practical completion certificate is issued: the point where the building can legally be occupied. However, it is acknowledged that some handover activities need to happen before this date and continue after it. These include activities like preparing a building manual to help the client move in.

As they usually do after you’ve had a new home built, the contractor needs to perform an evaluation of the property once the renovation is complete.

At stage 1, the plan for use strategy needs to be clear regarding expectations. Immediately following practical completion, hold a project performance session with the project team to find out how they feel about the project. Aftercare tasks – like seasonal commissioning or data collection – have different timelines, which means that the building would need to have been in use for some time before these tasks can take place.

RIBA Plan of Work Stage 1

The plan for use strategy needs to be clear regarding expectations. Immediately following practical completion, hold a project performance session with the project team to find out how they feel about the project.

RIBA Plan of Work Stage 7

This is when the building is being used, lasting until it reaches the end of its life.

When the project team finishes their work, they will close out the building contract and submit it to your organization.

At the end of stage 6, it’s essential to plan ahead for anything that may come up after the deliverable is done. If you need to hire anyone else for an extended period of time or provide ongoing client advice over a longer time frame, you’ll need to have your professional services agreement in place.

When clients are considering whether to do something about their building, they’re essentially starting over. They might first try to assess whether the building can be refurbished, reused for another purpose, or extended. If they find that none of these options are viable, then the building will either be demolished or disassembled with as many of its parts being recycled as possible.

When clients are considering whether to do something about their building, they’re essentially starting over.

They might first try to assess whether the building can be refurbished, reused for another purpose, or extended.

If they find that none of these options are viable, then the building will either be demolished or disassembled with as many of its parts being recycled as possible.

Clients may include some of these considerations in their Project Brief.

For example, they could ask the design team to produce test fits for other possible uses or make sure that methods for demolishing the building have been addressed during Stage 2.

As circular economy principles become more prominent in construction, these tasks will become more common.

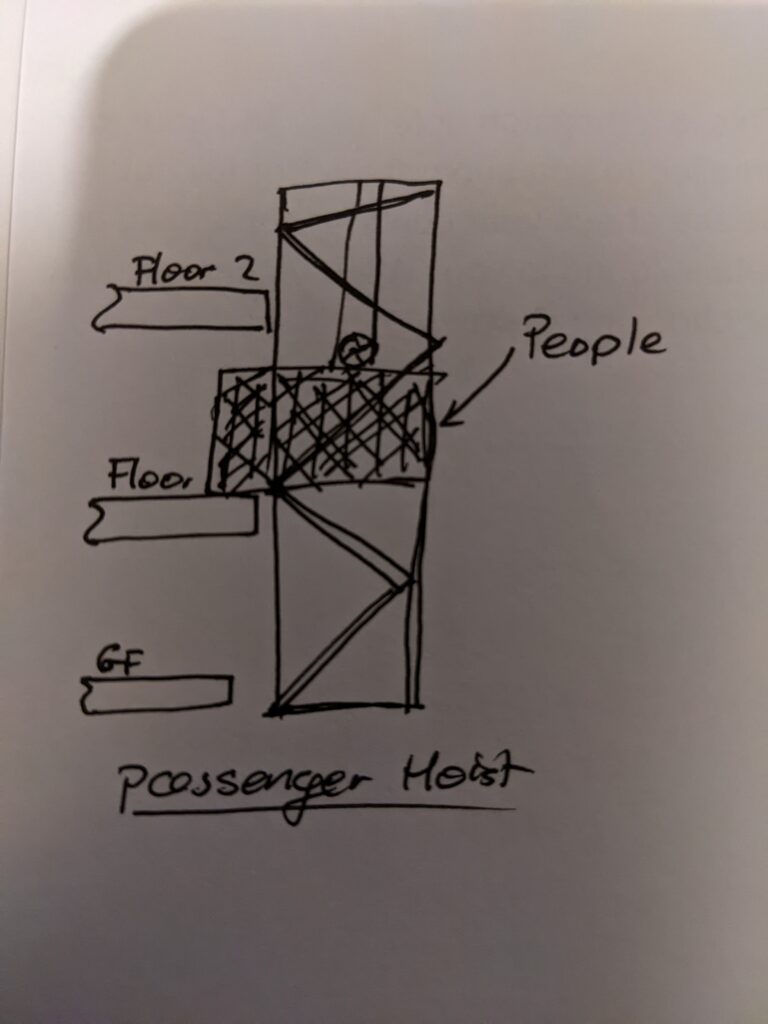

</img><figcaption>Passenger hoist</figcaption>

</img><figcaption>Passenger hoist</figcaption>